Edge Protection Strapping

Plastic Strapping Company on edge and corner protector

|

|

|

Despite the name cardboard or plastic edge protection frequently has additional other functions other than protect the edges of a product or carton when plastic strapping is applied to it, such as load stabilisation where for example the load comprised many small modules.. Edge protection comes in three forms, the well known plastic moulded corner pieces, flat rolls of plastic sheet, and cardboard and plastic angle available in cut to length form.

In terms of volume of pieces purchased then the moulded angles, available in a variety of sizes are the most popular They are manufactured from recycled polypropylene and quality is variable but generally acceptable, unless put into cold store conditions where the inferior versions go brittle and split. Corner protection pieces spread the load applied by the plastic strapping to a limited but often acceptable extent and prevent it damaging unprotected product edges or the tops of cartons. The other benefit is that it helps equalise the tension applied around all four sides of the pallet, as unless strapping can flow easily around the four corners issues can subsequently develop. When a plastic strap is tensioned with say 100 kgs load with tool on top of a pallet, the tension on the two vertical sides will be far less e.g. 60kgs and across the bottom, just 30 kgs. When a pallet is subsequently moved and transported, vibration will occur and the strap tension will tend to equalise i.e. slacken which could result in an unstable load.

The laminated cardboard/plastic cut to length edge protection pieces perform the same strap equalisation function and are more efficient at spreading load to the product resulting from a tensioned plastic strap. In addition they can be used to tie in vertical layers of product that would otherwise become unstable unless many plastic straps were applied. A typical situation where this benefit would apply would be where cartons were stacked vertically, one on top of the other, in vertical layers. There would be a tendency for the layers to break apart unless tied together at the top with edge protection strips, secured with two plastic straps.

Cardboard edge protection pieces can also be used vertically on the corners of a a palletised load to provide lateral stability where horizontal layers might have a tendency to move sideways.

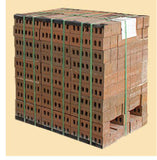

Flat plastic rolled corner corner protection is almost exclusively used for brick packaging where it is automatically dispensed across the top of cubed brick packs and held in place with five polyester straps applied with an automated strapping machine. As described earlier, the edge protection is used to maximise strap tension on all four sides of the brick pack, and prevent the vertical sheaves of bricks from parting.

It is also the case that the cardboard edge protection strips can also be positioned automatically on the tops of packs when part of an automated plastic strapping system. In general however all corner protection pieces are manually placed on a pallet, and this generally adds greatly to the time taken to a manual pallet strapping operation unless time can be saved elsewhere.

The most time consuming aspect of manually strapping a pallet is the need to drag strapping of a trolley – pull it over the top of the pallet – down the back face – thread it thru the pallet voids – walk to the front of the pallet – pick up the strap.... all this is repeated for every strap applied prior to putting the strap into the strapping tool.... and it’s a time consuming tiring activity. The time taken to get the straps around the pallet can be reduced by at least 50% – effort too! with a novel low cost mobile strapping machine manufactured by The Plastic Strapping Company Ltd – Nottingham. Click the link to view a short video showing how to get two straps around a pallet in approx six seconds!