Plastic Strapping Tool K12 Fault Finder and Parts List

Plastic Strapping Tool for Pallets

Strapping Tool K76

is used for applying polypropylene and polyester strapping 12mm wide, joining them with the serrated type K12 seal. It is important to check that the correct seals are being used as many copy seals now appearing in the market place can actually damage the tool and produce a far weaker joint. Copy seals can be a false economy as repairs generally cost more than any perceived savings on the cheaper seals. See how easy they are to use Watch the video

Damage to this tool is frequently caused by applying too much force when closing the clip, physical damage caused by bad handling and striking of the tool and lack of routine maintenance, all of these factors being applicable to this tool in particular as although precision engineered there are many small parts.

PSCL present this information but do not make any claims as to its accuracy or accept any liability arising from any recommedations made, and users of this tool are strongly advised to always refer to the manufacturers manuals before carrying out any self maintenance work. Only common faults are addressed.

K76 (12mm) Strapping Tool Fault Finder:

Many of the faults in the K76 originate in the handle assembly. Fig 1.

1. K76 Strapping Tool Ratchets slip when the tensioning lever is pushed forwards to apply tension:

Inspect both windlass ratchet 89 and ratchet wheel 97 for wear, missing gear teeth - also ratchet pivot pin 92 - it sometimes

fractures. To gain access to the handle of the tool remove all sideplate circlips and fix screws holding the chromed side plate to the

cast body of the tool. Exercise caution when separating the side plate from the body of the tool - hold it firmly as it is sprung loaded

and will try to rotate.

2. K76 Strapping Tool Ratchets allow slippage backwards when applying tension to the strap:

Refer to Fig 2: Failure to hold tension applied is caused either by worn lower ratchet (Item 111) or failure of the ratchet spring (Item

112). or damage to the spring hanger wire (Item 113).

3. K76 Ratchets slip when black button in the end of the handle is depressed and seal closure is attempted:

Inspect both windlass ratchet 89 and ratchet wheel 97 for wear - also ratchet pivot pin 92 - it sometime fractures. To gain access to

the handle of the tool remove all sideplate circlips and fix screws holding the chromed side plate to the cast body of the tool.

Exercise caution when separating the side plate from the body of the tool - hold it firmly as it is sprung loaded and will try to

rotate.

4. Completion of steps 1 - 3 does not resolve the problem?

Check the handle casting for signs of fracture particularly near the cutter actuating pin and where Item 95 enters the casting. Also

check that the Item described as 'Bow - 79 is tightly screwed into the thrust rod item 81. This does sometimes ( rarely) work loose.To

gain access to the thrust rod first remove screws (87) holding the lock plate ( Fig: 1) and then the lock pin 84. Pull push rod 94 and

spring 82 from shaft and insert a long shafted screwdrive to engage the slot in the end of the thrust rod and turn clockwise until tight.

5. K76 Cutter does not cut strap:

a. Remove strap cutter assembly (14) from tool by first removing two fix screws located directly under the base ( Fig 3) and sliding

the assembly backwards through the slot in the chrome side plate. Inspect cutting edges for signs of any damage i.e chipping etc

and if detected replace the blades as required. Pay particular attention to the lower blade as this incorporates a small 'pad' area

that comes into contact with the actuating pin ( Located in the end of the tensioning handle ( Fig: 1 Item 76)) that lifts the lower

blade every time a strap is cut. It is therefore a wear area and a grove is eventually worn in the pad so restricting the degree of lift

of the bottom cutter blade. An emergency temporary repair can be effected by carefully 'filling' the groove with weld and filing a

smooth profile pending fitting of a new replacement part.

b. Failure of the cutter actuating pin can also result in the lower cutting blade not lifting high enough to cut strap if the pin has become

loose in the tension lever casting. If this problem is identified then the only satisfactory way of effecting a long lasting repair is to

replace the tensioning handle.

6. K76 Seal block or clamp does not return to default position.

This is fairly common issue and can often be traced back to mis-use of the tool i.e. Too much force being applied when closing the

seals causing damage to the drive chain and consequent ill informed attempts to release it.

a. If the ratchet in the handle Fig 1: Item 100 checks out OK then sealing block drive gear (95) and sealing block quadrant gear ( 41)

should be checked for missing teeth and gears should be replaced if required.

b. Check quadrant gear return spring item 104 - locating lugs may be broken.

c. Check sealer block hanger Item 42. A small pin on the rear of the sealer block locates in the small hole in this hanger

and sometimes the hole can break open.... and or the pin can fracture.

d. It is common practice in an attempt to release a sealer block that is jammed in the 'down' position, to hit it with a hammer or to

insert an implement between the back face of the block and the machined face of the main casting in the area of the two vertical

slots. These procedures can cause serious damage to the casting i.e. result in a horizontal hair line fracture in the casting between

the two slots or damage the machined surface around the slots that the block normally slides up and down. To gain access to the

full machined area of the casting behind the sealer block remove four retaining fix screws Item 36.

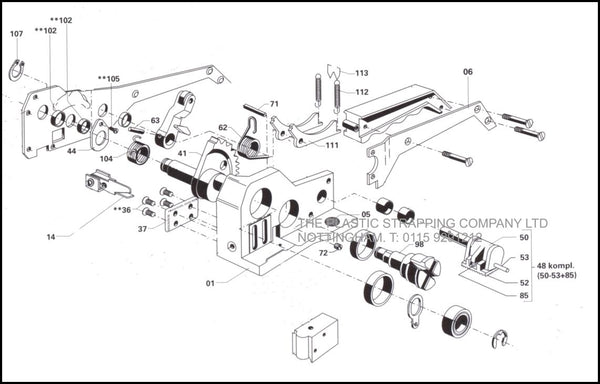

TO ORDER SPARES FOR THE K76 STRAPPING TOOL REFER TO MAIN DRAWING BELOW: