Description

Baling with polyester strapping machine

A recent survey revealed the astonishing fact that more than 80% of Companies that bale and recycle products and secure the bale with polyester plastic strapping buy their strapping from either the baling equipment supplier, or the provider of the actual plastic strapping tool as part of a tool rental agreement, both of which results in higher prices being paid for the strapping. Even a small percentage loading can cost these companies many hundreds and thousands of pounds extra every year. Competitive costs can be obtained from The Plastic Strapping Company Ltd of Nottingham, who do not sell Balers but are Strapping Machine Specialists.

All these Companies could probably cut their buying costs by purchasing the strapping more competitively from an independent source i.e. neither baler or strapping tool supplier.

Industries are changing the way of doing things in a more environmental friendly way, and baling machines in conjunction with polyester strapping are increasingly being recognised as a very effective recycling system and consequently becoming more central in giving waste materials a second valuable life.

A proper baler/baling machine can help greatly increasing your company’s revenue on recyclable waste, and can produce a positive Return On Investment within a relatively short time frame.

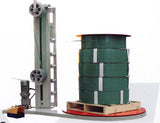

Because baling operations use a lot of polyester strapping, jumbo sized coils are now available which greatly reduce the number of times a strapping machine has to be reloaded, maximise uptime and reduce the amount of handling required with the normal sized coils. A jumbo Strapping Dispenser is required to handle these coils which can be loaded onto the unit by pallet loads as shown.

The Plastic Strapping Company Ltd Nottingham can rewind coils of polyester strapping that have been damaged during transit or handling, and cannot be fitted to a standard strapping machine coil holder.

How to Determine Which Type of Baler Is Right for You.

There are many types of Industrial Balers and Compactors including Horizontal, Vertical, Single Ram, Double Ram, Down stroke, Open-end, and Garbage Trash Compactors. Special functions such as automatic polyester strapping of the bale, using polyester automatic plastic strapping machines are available, along with the capability to shear and remove extra protrusions.

Some common types include:

Baling presses that use a large plate that comes down onto the material in the bin compressing it, then it is baled strapped using polyester strapping and friction weld handtools, and ejected.

Cardboard balers are designed to deal specifically with compressing and binding cardboard, usually for recycling. This type of baling press generally uses polypropylene strapping with buckles or friction weld banding tools.

Cardboard balers are designed to deal specifically with compressing and binding cardboard, usually for recycling. This type of baling press generally uses polypropylene strapping with buckles or friction weld banding tools.

Compactors are used to condense or crush material, and they have one or two mechanisms that press the material with extreme force to the desired size.

Crushers and flatteners compact and crush or flatten scrap material to improve handling, transportation, and disposal.

Double-ram balers have a separate ram for compressing recyclable material against a fixed wall and a second ram for ejecting the finished bale. Double-ram bales are generally denser, more uniform and use less polyester strapping than single-ram bales Double-ram balers are typically more expensive.

Double-ram balers have a separate ram for compressing recyclable material against a fixed wall and a second ram for ejecting the finished bale. Double-ram bales are generally denser, more uniform and use less polyester strapping than single-ram bales Double-ram balers are typically more expensive.

Downstroke baler is a baling device in which the compression ram and platen move vertically in the chamber. Garbage or trash compactors are a powerful device used to condense waste, trash and garbage.

Horizontal balers load from one end with the material traveling through to the other end in a horizontal motion. Open-end balers push the bale out and into an automated strapping machine installed immediately adjacent to the chamber exit. while a closed-end baler has a door at the end of the chamber.

Horizontal balers load from one end with the material traveling through to the other end in a horizontal motion. Open-end balers push the bale out and into an automated strapping machine installed immediately adjacent to the chamber exit. while a closed-end baler has a door at the end of the chamber.

Single-ram balers are fed by a conveyor that moves in sequence with the baling operation. Materials travel through the “in-feed” to an open charging box where they collect. A photo eye tells the machine when the box is full, then the ram pushes the materials into a chamber for baling and automatic tying.

Vertical balers load from the top or front of the machine and may have more than one bin in order to process different types or grades of material. They often have to be unloaded manually.

For Safe Baling Recommendations see HSE

http://www.hse.gov.uk/pubns/indg392.pdf

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.